The 10 Best Sheet Sanders Offers in UK - December 2025

- 230 watts of motor s and at 14,000 trajectories per minute, providing a superior finish

- Hook and loop plate allows for faster paper change, better dust extraction and increases grinding efficiency

- Dwe6411 14 sheet palm s ander 230w 230v

- Dustproof switch for increased durability

- Paper clips are provided for conventional abrasives

- Textured anti-slip top and body grips provide ultimate comfort and control during long-term use

- Quick-change hook and loop base and lever attachment

- Vacuum dust extraction port

- Large trigger switch and lock-on button

- Contoured main handle and front handle

- Includes dust extraction adaptor and 2 x sanding sheets

- Powered with 150W motor that delivers no load speed of 0 – 11000 rpm

- Compact and lightweight with 2 2 Grip positions, ensuring ease of use, firm grip and control during the applications

- Orbit diameter OD 2 mm to remove the coating quicker

- Ideal for a variety of sanding tasks including removing surface coatings or smoothing larger flat areas

- 1 Sanding sheet included

- 135w Orbital Sander 1/3 Sheet

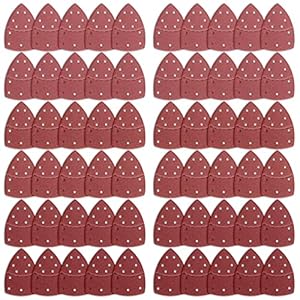

- 【Premium Quality Mouse Sander Pads】The mouse sanding pads made of premium aluminum oxide grain and high-strength resin,lasting and durable, and antistatic, very suitable for grinding and polishing.

- 【All Grit Grades Sanding Sheet】We have mouse detail sanding sheets of 6 different grits from coarse to fine,respectively are 40#/60#/80#/120#/180#/240#,10 sheets of each grit,totaling 60 sheets.The grits grade are printed on the sandpaper back,The lower the value, the rougher the polishing effect.The higher the value, the better the polishing effect.

- 【Backing Technology 】The sander pads with hook and loop backing, the mouse detail sanding sheets are easy and quick to stick on most palm sander,pre-punched with 11 holes for dust extraction.

- 【Size】150*105*10 mm, can be used for most palm sander at this size, such as BOSCH Multi-Sander PSM 100A, All Oscillating Multi-Tool Makita DTM51Z, DWE315KT, Tacklife PMT01B and so on.

- 【Wide application】The mouse detail sanding sheets are widely used to wiping rust on metal surfaces and polishing or grinding nonmetallic objects, such as plastic, wood, rubber, leather, glass, stone application for buffing and polishing.

- Mouse Grinder Material The Black Decker mouse sanding pads are made of high quality aluminum oxide grain and high strength resin, durable and anti-static, good choice for grinding and polishing. Back: hook and loop, easy and quick to stick, sturdy and durable.

- 【All Grits Sanding Sheet】Includes 4 different grits of sandpaper: 40# 60# 80# 120#, 10 sheets of each grit, total 40 sheets, and the grits are printed on the back of the sandpaper to make it easy to identify.

- Size of Black Decker Mouse Sander - 170mm x 140mm x 95mm, with 4 holes for dust extraction, prevents obstacles, for 140mm sandpaper for Black and Decker mouse sanders.

- Applicable target grinding discs: These standard size sanding sheets are suitable for 140mm detail sanders. With Velcro sanding sheets, the mouse detail sanding sheets are easy for you to quickly stick to detail sanders.

- 【MULTI-PURPOSE OF SANDING PADS】Mouse sanding sheets are widely used for wiping rust on metal surfaces and polishing or sanding non-metallic objects such as plastic, wood, rubber, leather, glass, stone and more.

- Grip area with non-slip soft surface

- Dust-proof ball bearings for long machine life

- Ideal Product

- Premium Sanding Sheets: Made with superior aluminum oxide abrasives, these sandpapers are tailored for a 93 x 185mm rectangular sander.

- Comprehensive Grit Options: Offering a full range of grits from coarse to fine (40/60/80/120/180/240/400/600), sand paper are the go-to choice for any sanding and polishing requirements.

- Efficient Hook and Loop System: Sander pads ensures swift installation and removal, with a firm grip that keeps the sandpaper securely in place throughout the process.

- Advanced Dust Hole Technology: Equipped with eight dust holes, this design significantly reduces dust and debris, preventing sanding paper blockage and boosting productivity.

- Universal Compatibility: Ideal for sanders of the matching dimensions, these sanding sheets are perfect for a diverse range of sanding projects, whether large or small, and are suitable for various materials such as wood, metal, non-metals, plastics, walls, and painted surfaces.

- The flexible and compact orbital sander for a clean sanding pattern of flat surfaces

- Large ergonomic gripping surfaces for comfortable working and precise guidance

- Quick-Fix system for abrasive paper with hook and loop adhesion and additional clamping device for conventional abrasive paper

- Dust extraction adapter for the greatest possible cleanliness during continuous sanding work

- Includes 3-piece sandpaper set for quick start

- MAKES EASY WORK OF DETAIL SANDING: Easy to use and incredibly versatile the BLACK+DECKER Mouse is the perfect tool for tackling intricate and detailed sanding jobs. Whether you’re refinishing furniture, removing paint or rust, or working on tight corners and narrow spaces, the Mouse sander delivers smooth results every time.

- RECOGNISED ALL OVER THE WORLD: The BLACK+DECKER Mouse sander has been a staple in DIY tool boxes around the World since 1998 and is often credited as one of the original detail sanders. Its unique shape and functionality set a standard for detail sanders in the market.

- POWERFUL 55W MOTOR: Equipped with a powerful 55W motor that delivers an impressive 11,000 RPM, allowing you to complete sanding projects quickly and efficiently.

- COMPACT DESIGN: Inspired by the computer mouse, the BLACK+DECKER Mouse gets you closer to the work surface for greater control over intricate, detailed sanding jobs.

- LIGHTWEIGHT AND ERGONOMIC: Features rubber grips for superior comfort and precise control, making it easy to handle and manoeuvre.

- TEAR DROP SHAPED BASE: Provides easy access to tight corners and intricate spaces, allowing for precise sanding in areas that are typically hard to reach with larger conventional sanders.

- HOOK & LOOP SANDING SHEETS: Quick-fit hook & loop sanding paper for quick and easy sanding sheet fitment.

- ROCKER SWITCH: The rocker-style on/off switch enables continuous motor operation, allowing you to move your hands freely around the sander for enhanced comfort and a more secure grip.

- DUST EXTRACTION PORT: Don’t worry about making a mess while you’re sanding - simply attach your vacuum cleaner to the port to suck away the dust, ensuring your work area stays clean.

- INCLUDES: 6 sanding sheets and vacuum cleaner dust extraction attachment.

Compare Sheet Sanders and find the most suitable offer.

Sheet sanders, also known as finishing sanders or palm sanders, are versatile power tools used for smoothing and refining wood, metal, and other surfaces. They are particularly effective in removing scratches, blemishes, and imperfections, creating a smooth and polished finish. These sanders are commonly used in woodworking and carpentry projects, furniture restoration, and DIY home improvement tasks.

Sheet sanders are handheld tools that feature a rectangular sanding pad, usually measuring around 4 x 9 inches or 4 x 11 inches. The pad holds a sheet of sandpaper firmly in place, allowing for easy and quick changes when the sandpaper becomes worn or damaged. The sanding pad moves in orbital or random orbital motion, ensuring a smooth sanding action without leaving visible swirl marks. This makes sheet sanders ideal for final finishing touches or preparing surfaces for painting or staining.

One of the advantages of sheet sanders is their lightweight and compact design, which allows for easy maneuverability and control. They are comfortable to grip and operate, minimizing fatigue during extended use. Sheet sanders are also generally affordable and readily available in various price ranges, making them suitable for both professional craftsmen and home DIY enthusiasts.

When selecting a sheet sander, it's important to consider the power source. Sheet sanders are available in both corded and cordless models. Corded sheet sanders provide continuous power, eliminating the need to recharge or replace batteries. On the other hand, cordless sheet sanders offer greater mobility and flexibility, making them convenient for use in hard-to-reach areas or locations without a power outlet.

In conclusion, sheet sanders are essential tools for achieving a smooth, polished finish on wood, metal, and other surfaces. With their versatile functionality, ease of use, and affordability, sheet sanders are a valuable addition to any workshop or toolbox. Whether for professional projects or DIY tasks, sheet sanders provide efficient results and allow for precise sanding control.

** "Free Delivery" means that this is possible under the given conditions at the time of data retrieval from the relevant provider, but cannot be guaranteed. It is technically not possible to provide information in real-time. The shipping costs may vary under certain circumstances (different provider, place of delivery, etc.). The shipping costs shown in the further ordering process apply.

Other IMPORTANT INFORMATION that we ask you to take note of:

We may receive a commission if you make a purchase via the links on our site. This has no impact on the placement of the products on our site. Our website is part of amazon associates program - Amazon, Amazon Prime, the Amazon Logo and Amazon Prime Logo are registered trademarks of Amazon, Inc. or its affiliates.

Disclaimer:

1. The prices shown may have risen since the time we last updated them.

2. The actual price of the product on the seller’s site at the time of purchase will govern the sale.

3. It is not technically possible for the prices displayed above to be updated in real-time.

What is a sheet sander and how does it differ from other sanders?

A sheet sander, also known as a finishing sander or palm sander, is a versatile power tool used for smoothing and polishing wood, metal, plastic, and other materials. Unlike other sanders, it uses a standard size sheet of sandpaper attached to the base of the tool with a clip or adhesive. The sandpaper is easily replaceable and can be found in various grits for different levels of abrasion.

One of the main differences between a sheet sander and other types of sanders, such as belt sanders or orbital sanders, is its small size and lightweight design. This makes it ideal for working on smaller surfaces and hard-to-reach areas that larger sanders cannot access. It is also easier to control and maneuver, making it a popular choice among DIY enthusiasts and professionals alike.

Another advantage of a sheet sander is its ability to produce a smooth and even finish. It operates by vibrating the sandpaper at high speeds, creating a uniform surface without leaving swirl marks or scratches. This makes it an excellent choice for sanding down lacquered or painted surfaces before applying a new coat of finish.

Sheet sanders are also relatively affordable and easy to use. They typically come with a dust collection bag or port, which helps to keep your workspace clean and free of debris. Many models also include ergonomic handles and soft-grip pads for added comfort during long periods of use.

In conclusion, a sheet sander is a useful tool for anyone who needs to sand and polish various materials, particularly in hard-to-reach areas. Its easy replacement of sandpaper, lightweight and ergonomic design, and the ability to create a smooth and even finish make it a popular choice for woodworkers, metalworkers, and DIY enthusiasts alike. By choosing a sheet sander, you can save time and effort while achieving professional results.

What are some common uses for a sheet sander?

A sheet sander, also known as a finishing sander, is a versatile tool that is essential for any DIY enthusiast or professional woodworker. It is designed to help sand and smooth wooden surfaces, making them ready for a finishing coat or paint. Here are some common uses for a sheet sander.

1. Sanding flat surfaces

One of the most common uses of a sheet sander is to smooth out large, flat surfaces such as tabletops, doors, and floors. The tool is equipped with rectangular sandpaper sheets that come in varying degrees of coarseness, making it easy to adjust the level of sanding required. With its powerful motor and large sanding base, the sheet sander quickly and efficiently removes any rough, uneven patches.

2. Removing paint and varnish

Another common use of a sheet sander is to remove old paint or varnish from wooden surfaces. This is particularly useful when refinishing or repainting furniture, cabinets, or walls. The sheet sander makes quick work of removing layers of old paint or varnish, revealing a smooth, clean surface underneath. Just be sure to use the right type of sandpaper for the job and work in a well-ventilated area to prevent inhaling hazardous fumes.

3. Sanding difficult-to-reach areas

While a sheet sander is great for sanding flat surfaces, it can also be used to sand hard-to-reach areas that are difficult to sand by hand. This makes it an ideal tool for sanding corners, edges, and curved surfaces. With its triangular sanding base, the sheet sander can easily access tight spaces and contours, making it a valuable addition to any DIYer or woodworker's toolkit.

4. Smoothing out rough edges

If you've ever cut a piece of wood with a saw, you know that the edges can be rough and uneven. A sheet sander, with its ability to sand flat surfaces and edges, can quickly smooth out those rough edges, making them more presentable and less prone to splintering. This is particularly important when building furniture or other items where people will be in close contact with the wood.

5. Sanding between coats

When applying a finish or paint to wood, it's important to sand between coats to ensure a smooth, even finish. A sheet sander, with its ability to sand flat surfaces and edges, is perfect for this job. It can quickly and evenly sand the surface, making it ready for the next coat of finish or paint.

6. Refinishing old furniture

Finally, a sheet sander is a valuable tool for refinishing old furniture. Whether you're restoring a family heirloom or picking up a piece of furniture from a thrift store, a sheet sander can help remove old paint or varnish, smooth out rough edges, and prepare the surface for a new coat of finish or paint. With its versatility and power, the sheet sander is an essential tool for any furniture restoration project.

Can a sheet sander be used on curved surfaces?

When it comes to sanding curved surfaces, a common question often arises: can a sheet sander be used for this purpose? The answer is somewhat complicated because while a sheet sander can technically sand curved surfaces, it is not the best tool for the job. This is primarily because sheet sanders use rectangular sheets of sandpaper that are not designed to conform to curved surfaces.

However, if you must use a sheet sander on a curved surface, there are a few things you can do to improve your chances of success. One of the first things you should do is select the right grit of sandpaper. Depending on the curvature of the surface you are sanding, you may need a finer grit sandpaper to ensure that the sandpaper conforms to the surface more easily.

Another key consideration when using a sheet sander on a curved surface is to ensure that the sandpaper is attached securely to the sander. This helps to ensure that the sandpaper remains in place as you work, which can be especially important if you are sanding a particularly challenging surface.

It's also essential to keep the sander moving in a consistent motion across the surface you are sanding. This will help to ensure that you do not apply too much pressure in one area, which can cause unpleasant visual blemishes and mars on the surface.

However, keep in mind that using a sheet sander on a curved surface may not be the best option for your project. There are specialized sanding tools available that are designed specifically for curved surfaces, such as spindle sanders and oscillating sanders. These tools can provide more control and precision when sanding difficult surfaces, and they can help to ensure a smoother finish.

In conclusion, while a sheet sander can technically be used to sand curved surfaces, it is not the most effective tool for the job. If you must use a sheet sander for a curved surface, follow the best practices mentioned above and consider other sanding tools for challenging curves. Ultimately, selecting the right sanding tool for your project can make a tremendous difference in the quality of the finished product.

How do I choose the right grit sandpaper for my sheet sander?

When it comes to choosing the right grit sandpaper for your sheet sander, there are a number of factors to consider. The grit of the sandpaper determines how coarse or fine the abrasive particles are, and different grits are suited for different sanding tasks. In general, the coarser the grit, the more material it will remove, while finer grits are better suited for smoothing and finishing.

One important factor to consider when choosing sandpaper grit is the type of material you will be sanding. Harder materials such as metal or hardwood will typically require a coarser grit to effectively remove material, while softer materials such as pine or plastic will require a finer grit to achieve a smooth finish without damaging the surface.

Another important consideration is the level of finish you are aiming for. If you are looking to simply roughen up a surface in preparation for painting or another finishing process, a coarser grit such as 60 or 80 may be appropriate. However, if you are looking to achieve a high-quality, polished finish, you may need to work up to finer grits such as 150 or 220 to achieve the desired result.

It's also important to consider the load on the sandpaper when choosing the right grit. If you're working with a large surface and need to remove a significant amount of material, a coarser grit may be appropriate. However, if you're working with a small area or delicate material, a finer grit may be more suitable to avoid damaging the surface.

Finally, it's important to consider the compatibility of the sandpaper grit with your sheet sander. Different sanders may require different sizes or types of sandpaper, and using the wrong grit or type of sandpaper can lead to poor results or even damage to your equipment. Be sure to consult the manufacturer's specifications or instruction manual to choose the right grit and type of sandpaper for your sheet sander.

Overall, choosing the right grit sandpaper for your sheet sander requires careful consideration of the material you'll be working with, the level of finish you're aiming for, the load on the sandpaper, and the compatibility with your equipment. With a little research and experimentation, you can find the right grit to achieve the perfect finish for your project.

What is the lifespan of a sheet sander and how do I maintain it?

Sheet sanders are versatile tools that can help you achieve a smooth and even finish on a wide range of surfaces. However, like any mechanical tool, sanders require maintenance to extend their lifespan and ensure their optimal performance. In this article, we will discuss the average lifespan of a sheet sander and how to maintain it.

The lifespan of a sheet sander can vary depending on the quality of the tool and the frequency and intensity of its use. Typically, a good quality sheet sander can last for several years if properly maintained. However, if the tool is not taken care of, it may start to break down and wear out much sooner than expected.

To extend the lifespan of your sheet sander, you should start by properly storing it when not in use. Avoid leaving it in damp or humid places as this can cause the interior parts of the tool to rust or corrode. Instead, store your sheet sander in a dry and well-ventilated area.

Regular cleaning is also essential to maintain your sheet sander. Make sure to remove any dust, debris, or other particles that may have accumulated on the tool after use. You can use a soft brush to clean the sanding pad and a vacuum cleaner to remove any remaining residue. Additionally, you can wipe down the sander with a damp cloth to remove any stubborn dirt or stains.

Another important aspect of maintaining your sheet sander is to replace any worn-out parts. Over time, the sanding pad, sandpaper, and other components may start to deteriorate. To ensure optimal performance, it is important to replace these parts as soon as you notice signs of damage or wear.

In summary, the key to extending the lifespan of your sheet sander is to properly store it, regularly clean it, and replace any worn-out parts. By following these simple maintenance tips, you can ensure the optimal performance and longevity of your sheet sander, helping you achieve a smooth and even finish on any surface.

Can a sheet sander be used for heavy duty sanding projects?

The sheet sander is a versatile tool that is suited for light to medium sanding projects. It is designed to sand flat surfaces such as doors, tables, and wooden floors. The sheet sander excels in smoothing out rough patches and removing light scratches. However, when it comes to heavy-duty sanding, the sheet sander may not be the best option.

For heavy-duty sanding projects, you may want to consider a belt sander. Belt sanders are capable of removing layers of paint, rust, and other stubborn materials with ease. They have a powerful motor and can handle large surfaces quickly. However, belt sanders are not recommended for finishing work or delicate pieces because they can be too aggressive.

Another option for heavy-duty sanding is a random orbit sander. Random orbit sanders combine the speed of a sheet sander and the strength of a belt sander. They use a circular motion with a random orbit pattern to provide a smooth finish on any surface. These sanders are versatile and ideal for removing paint, varnish, and other coatings.

If you already have a sheet sander and need to sand a large, flat surface, you can still use it for heavy-duty sanding. However, you may need to change the sandpaper frequently. Using a coarse grit sandpaper will make it easier to remove rough patches and other imperfections. Make sure the sandpaper is securely attached to the sander and avoid applying too much pressure, which can cause the sandpaper to wear out faster.

In conclusion, sheet sanders are great for light to medium sanding projects but may not be the best option for heavy-duty sanding. Belt sanders and random orbit sanders are better suited for those types of tasks. However, if you need to use a sheet sander for heavy-duty sanding, be sure to change the sandpaper frequently and avoid using too much pressure. Proper maintenance and care of your sander will ensure that it lasts for years and can handle a variety of sanding projects.

What safety precautions should I take when using a sheet sander?

A sheet sander is a handheld power tool used for sanding wood and other materials. It can be a useful tool for DIY enthusiasts and professionals alike. However, it is important to take certain safety precautions when using this tool to prevent accidents and injuries. Here are some safety tips to keep in mind when using a sheet sander.

Firstly, it's essential to wear personal protective equipment (PPE) when using a sheet sander. This includes safety goggles to protect your eyes from flying debris, a dust mask to prevent you from inhaling sawdust and other particles, and earplugs to protect your ears from loud noise. Make sure your PPE is correctly fitted and comfortable to wear so that you can concentrate on using the tool.

Secondly, make sure that the sheet sander is in good working condition before using it. Check the power cord for any cracks or damage, and ensure that the sander's switch is functioning correctly. If you notice any problems or damages, do not attempt to use the sander and have it repaired by a professional.

Thirdly, be mindful of your surroundings when using a sheet sander. Ensure that your workspace is free from any tripping hazards, and that the power cord is out of the way. Keep the sander away from any water or liquids and avoid using it in damp or wet conditions.

Fourthly, never apply too much pressure while sanding with the sheet sander. Allow the tool to do the work and use gentle and steady pressure. Applying excessive pressure can cause the sander to overheat, damaging the tool or causing a fire hazard. Furthermore, avoid using the sander to sand materials that are too hard or tough for the tool to handle.

Finally, when using the sheet sander, make sure you have a clear understanding of how to operate the tool. Read the manufacturer's instructions carefully before using the tool for the first time. Additionally, ensure that the sander is switched off and unplugged from the power supply when changing the sandpaper or making any other adjustments.

In conclusion, taking the necessary safety precautions while using a sheet sander can help prevent injuries and accidents. Always wear PPE, ensure the tool is in good working condition, be mindful of your surroundings, apply steady pressure while sanding, and understand how to operate the tool. By following these safety tips, you can use a sheet sander with confidence and achieve great results in your woodworking projects.

Do sheet sanders come with dust collection systems?

Sheet sanders are power tools used to smooth and polish surfaces, such as wood, metal, and plastic. These sanders are versatile and can handle various tasks, including sanding large surfaces, removing old paint and finishes, and shaping edges. However, the dust generated during the sanding process can be hazardous to one's health and can create a mess in the work area. Thus, it is essential to have an efficient dust collection system to minimize dust exposure and keep the work area clean.

Fortunately, many sheet sanders come with dust collection systems that help to reduce dust emission and create a cleaner working space. The most common dust collection system for sheet sanders is the dust bag, which attaches to the sander and captures dust as it is generated. The collected dust is then disposed of conveniently. These dust bags are effective in collecting larger debris but may not be as efficient in filtering fine dust particles.

Another type of dust collection system is the vacuum attachment. Some sheet sanders are compatible with vacuums, which attach to the sander and suck up dust as it is generated. Vacuum attachments are more efficient than dust bags as they collect both large debris and fine dust particles. Moreover, vacuum attachments are suitable for long hours of sanding as they eliminate the need to empty dust bags frequently.

However, not all sheet sanders come with dust collection systems. Some models may come with dust ports that allow for the attachment of dust bags and vacuums, but others may require purchasing these attachments separately. It is crucial to check the product specifications before purchasing a sheet sander to know if it comes with a dust collection system or if additional attachments are required.

Lastly, it is essential to note that a dust collection system only works efficiently if properly maintained. Dust bags should be emptied regularly, and vacuum filters should be cleaned or replaced as needed. Neglecting to maintain the dust collection system can lead to reduced performance, clogging, and damage to the sander.

In summary, sheet sanders come with various dust collection systems, including dust bags and vacuum attachments, to reduce dust exposure and maintain a clean workspace. It is important to check the product specifications before purchasing a sheet sander to know if it comes with a dust collection system or if additional attachments are needed. Proper maintenance is also crucial to ensure the efficient performance of the dust collection system.

Is a sheet sander a good tool for refinishing furniture?

When it comes to refinishing furniture, there are several tools you can use to achieve a smooth and flawless finish. One of the most commonly used tools is the sheet sander. A sheet sander is a hand-held power tool that is used to sand flat surfaces such as tabletops, dressers, and cabinets.

One of the benefits of using a sheet sander is that it's quick and efficient. The tool is designed to sand large areas quickly, which is perfect for refinishing furniture. With a sheet sander, you can remove the old finish and smooth out any imperfections in a fraction of the time it would take to do it by hand.

Another advantage of using a sheet sander is that it's easy to use. Even if you're a complete beginner, you can quickly learn how to operate the tool and achieve professional-quality results. All you need to do is attach the sandpaper to the sander, turn it on, and move it back and forth over the surface of the furniture.

However, when using a sheet sander, it's important to be careful and use the right grit sandpaper. Depending on the level of refinishing you want to do, you may need to use different grits of sandpaper. If you start with a grit that's too coarse, you may end up damaging the surface of the furniture, but if you start with a grit that's too fine, you may not be able to remove the old finish effectively.

In addition, sheet sanders can create a lot of dust, which can be harmful if inhaled. It's important to wear a mask and protective eyewear when using the tool and to work in a well-ventilated area.

Overall, using a sheet sander can be an effective tool for refinishing furniture. It's quick, efficient, and easy to use, making it a great option for DIYers and professionals alike. However, it's important to be careful and use the right grit sandpaper and protective gear to ensure that you achieve the best results and stay safe while using the tool.

Can a sheet sander be used on metal surfaces?

Sheet sanders are commonly used to sand down wood and other materials in DIY and carpentry projects. However, they can also be used on metal surfaces. Before using a sheet sander on metal, it is important to consider a few things to ensure successful results.

Firstly, it is important to choose the right sandpaper. For metal surfaces, sandpaper with a higher grit is recommended as it will be more effective in removing rust and other imperfections on the metal surface. It is important to choose sandpaper with a grit of at least 80 to ensure that it is strong enough to handle the metal surface.

Secondly, it is important to ensure that the metal surface is clean and dry before using the sheet sander. Any debris or dirt on the surface can get caught in the sandpaper and cause scratches or damage to the metal surface. It is recommended that a clean cloth and a degreaser be used to clean the surface before sanding.

Thirdly, it is important to use the correct technique when sanding metal with a sheet sander. Unlike sanding wood, where a circular or back and forth motion is recommended, sanding metal requires a smooth and steady motion in one direction. This will help to avoid creating scratch marks on the metal surface and ensure a smooth finish.

It is also important to consider the safety precautions when using a sheet sander on metal. Metal particles can fly off when sanding, so it is recommended to wear protective clothing and eyewear to prevent any injuries. Additionally, it is important to use a dust extractor or a mask to prevent inhaling any metal particles.

In conclusion, a sheet sander can be used on metal surfaces with the right sandpaper, technique, and safety precautions. It is important to choose the right grit of sandpaper, clean the metal surface before sanding, use the correct technique, and take the necessary safety precautions to ensure a successful and safe sanding experience.